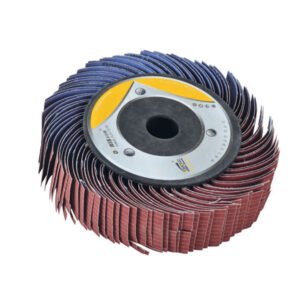

Flap Wheel

Feel free to drop us any questions, we welcome product inquiries. You can reach out via the button form below or the WhatsApp Icon and we’ll respond within 1-2 working days.

Flap Wheel Frequently Asked Questions

Exploring the Functionality of Flap Wheels

Flap wheels represent a dynamic and adaptable abrasive instrument. They are designed as wheel attachments, where numerous abrasive flaps radiate outward from the central hub.

Each flap is uniformly sized, crafted from x-weight cloth combined with abrasive grains, similar to the texture of sandpaper. As flap wheels are used, they gradually wear away, revealing new abrasive layers for consistent performance and extended lifespan.

Such abrasives are particularly effective for tasks involving tubes and pipes, as well as on contoured or uneven surfaces, and over extensive areas.

Utilizing Flap Wheels in Various Applications

Owing to their versatility, flap wheels can be employed in numerous ways, including:

- Efficient material removal

- Deburring or deflashing

- Eliminating rust

- Cleaning along weld lines

- Removing weld spatter

- Finishing and polishing of metals or wood

- Mild grinding activities

- Smoothing out surfaces

- Sharpening various tools

Flap wheels are suitable for a wide range of materials, from ferrous and non-ferrous metals, such as stainless steel, iron, brass, and aluminum, to non-metallic substances like plastics, wood, and fiberglass.

Types of Flap Wheels: Unmounted and Mounted

What are the advantages of using flap wheels over other abrasive tools?

Flap wheels offer unique advantages such as even wear, which exposes fresh abrasive grains for consistent cutting performance over time.

They are also highly flexible, making them ideal for working on irregular or contoured surfaces. Their ability to provide a smooth finish with minimal gouging is particularly beneficial for precision work.

Can flap wheels be used on all types of grinders?

Flap wheels are versatile and can be attached to various types of grinders.

However, it’s important to match the flap wheel’s arbor hole size with the grinder’s spindle size for proper fitting. They can be used with bench grinders, angle grinders, and die grinders, among others.

How do you choose the right grit size for a flap wheel?

The grit size of a flap wheel depends on the nature of the task. Coarser grits (e.g., 40-60 grit) are suitable for aggressive material removal and deburring, while finer grits (e.g., 80-120 grit) are ideal for finishing and polishing. The material you’re working on also influences the choice of grit size.

Are flap wheels safe for all materials?

Flap wheels can be used on a wide range of materials, including metals, wood, plastics, and fiberglass. However, it’s important to select the right type of abrasive grain for the material. For example, aluminum oxide grains are great for metal, while silicon carbide grains are better for non-metallic materials.

How do I know when to replace a flap wheel?

A flap wheel should be replaced when the abrasive flaps wear down to the point where they are no longer effective. This is usually noticeable when the tool requires more pressure to achieve the desired result, or when the finish quality decreases.

Can flap wheels be used for both wet and dry applications?

Most flap wheels are designed for dry applications. However, there are specific types that can be used for wet applications. Always check the manufacturer’s recommendations before using a flap wheel in a wet environment.

Contact

Mobile/WhatsApp: +86 186 3753 0319 (WhatsApp & Calls available between Mondays to Fridays, 9 am to 6 pm)

Email: contact@niaabrasives.com

Order/Quotation Request Form